While the Lean tool Kanban and its steps are fairly straightforward in terms of their applicability, calculating Kanban cards require a bit more effort. Therefore, here are the 5 key considerations you need to keep in mind to calculate Kanban cards:

Key Consideration 1: Know your demand

To calculate Kanban cards, use statistical analysis to discover demand by product type. For instance, a basic calculation of demand is ‘average sales’ by product type in the past year. See the graph below. Evidently, it shows the average demand by product type using past data:

Figure 1 – Estimating customer demand from historical data

Key Consideration 2: Know your time elements

By referring to the diagram below, observe the base number of Kanban and quantity per Kanban card on time. For example, Kanban quantity for purchase will depend on transit time!

Figure 2 – Consider time elements to define the number of Kanban

Key Consideration 3: Level load

To effectively calculate Kanban cards, this consideration is crucial. In the previous diagram, you’ll notice that ‘lot production time’ is a small portion of planned lead time. Therefore, consider a safety (time-based) to ensure you don’t ship late to the customer! Most importantly, you must understand takt time, planned cycle time, and load levelling to demand and product mix. Take a look at a graphical representation:

Figure 3 – Level the load to takt time.

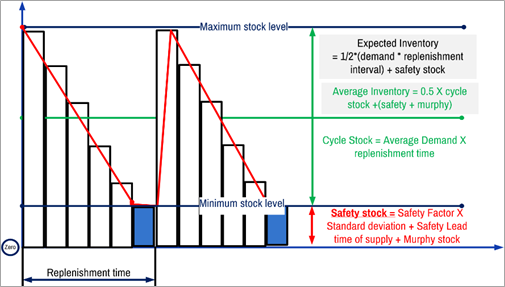

Key Consideration 4: Prevent ‘stock out’ condition – maintain the minimum stock levels

The figure below explains the relationship between the following:

- Firstly, replenishment time

- Secondly, maximum and minimum stock levels

- Thirdly, expected and average inventory

- Fourthly, cycle stock

- Lastly, safety stock calculations

Figure 4 – Avoid a ‘stock out’ scenario

Key Consideration 5: Calculate the Kanban quantities

Use suitable calculations to discover the number of Kanban, daily output, lead time, safety margins, and pallet capacity. Most importantly, modify the formulae to suit your business.

Figure 5 – Formulae to calculate the number of Kanban

Therefore, the key considerations to calculate the number of Kanban cards include implementing the prerequisites, knowing the demand, deciding on a pull versus push model, knowing your order-to-ship time break up, and determining the re-order levels scientifically. Hence, I recommend you pick up a good book on Kanban or hire an experienced lean facilitator to implement a Kanban system in your company.

A Visual Communication System for Kanban: Empty Slots Trigger Action

Figure 6 – Maintain Kanban system ‘visually’ in the factory

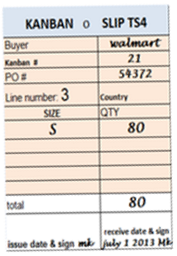

The pictures below describe a Kanban card and a Kanban board, which have been implemented in one of our client’s places. You must design your own Kanban card. Moreover, you may make mistakes. However, that’s how you’ll learn. Evidently, it will take a few iterations before you discover the most suitable Kanban system for your business and working. Check out the most frequently asked questions regarding Kanban!

Image 1 – Example of a Kanban card

Image 2 – Kanban board and cards