There is no ‘one way’ to carry out Lean, and there is no way to carry out Lean without putting necessary ground work in place first.

Why should you wish to do Lean? – “To get rid of non value added activities and time” is the most common answer I receive from almost everyone I’ve met in my work engagements. In my view if Lean should bring happiness and peace to the company and its customers. Here is one incident I wish to share with you. In a company I asked a worker who did 500 pieces in an hour using Lean single piece flow approach. She and her team using traditional approach could achieve only 250 pieces earlier. When I asked “What is your feeling after achieving this feat?” She said, “I am happy that I could achieve this number and still not feeling tired”. Lean should aim at giving a company and its workers a “sense of achievement”, if it doesn’t, Lean placement will turn to become ‘program of the month’ sooner than later.

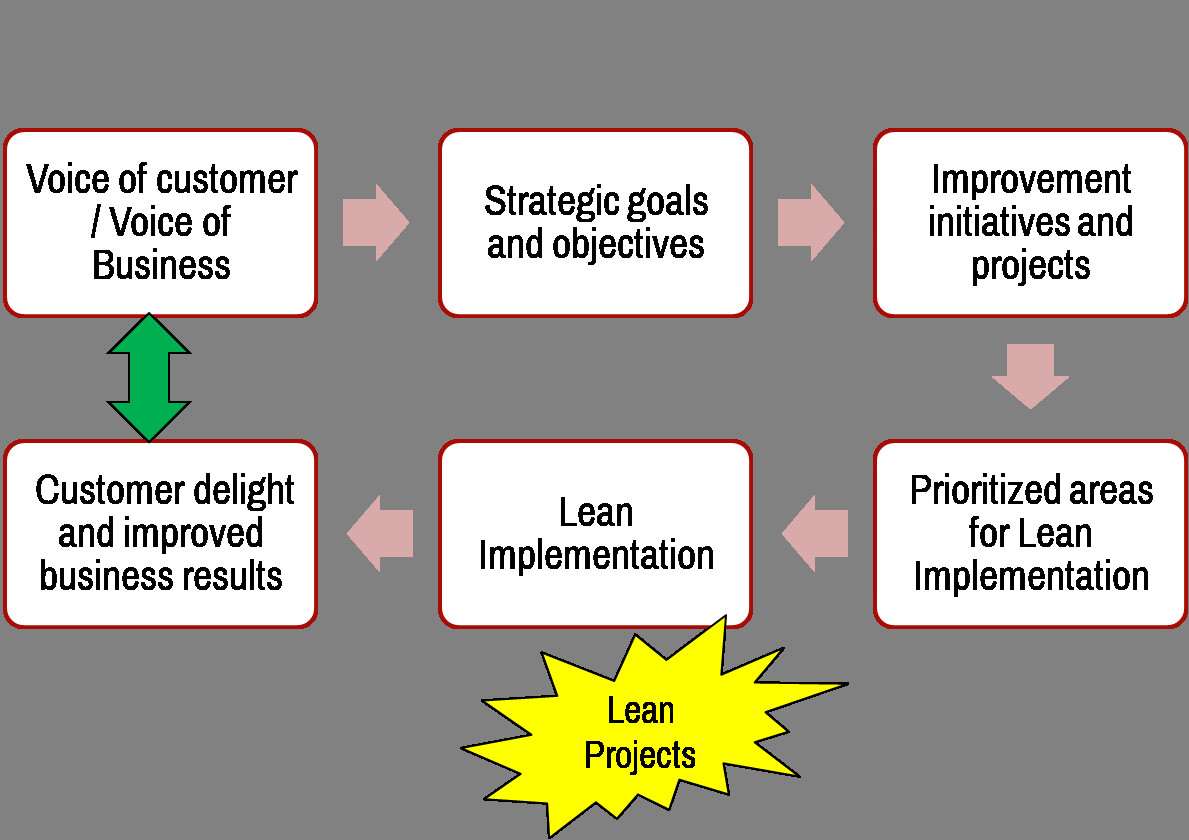

Ground work 1: Connect Lean to the the big picture

Lean should be considered as means to achieve company’s long term vision and objectives. If this is missing, it may become ‘program of the month’.

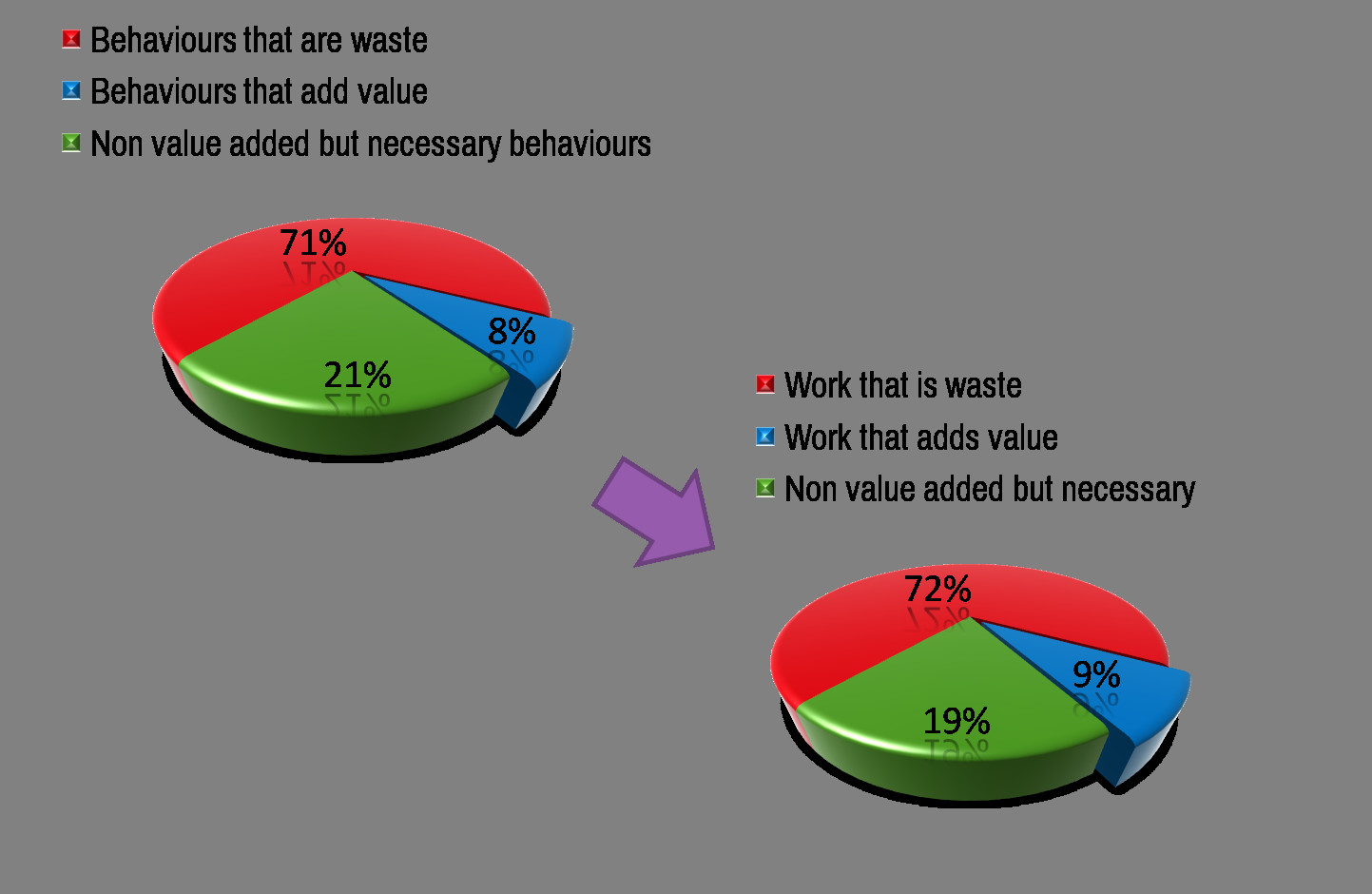

Ground work 2: Recognize and follow behaviors essential for Lean journey

If a company tries to implement Lean without considering what behaviors make it click, it is preparing to fail. Bob Emiliani, in his book “Practical Lean Leadership” suggests fat behaviors drive wastes in an organization. Examples of fat behaviors include micromanaging, bully, blame, misleading, disrespectful of co-workers, public humiliation and many more. As a leader you should first recognize and streamline ‘fat behaviours’, if they exist.

This simple Shingo behavior assessment scale may be of further help to Leaders and Lean practitioners. If a company’s employees are at Level 1 (Leaders included), leaders should not expect results relevant to behavior level 5.

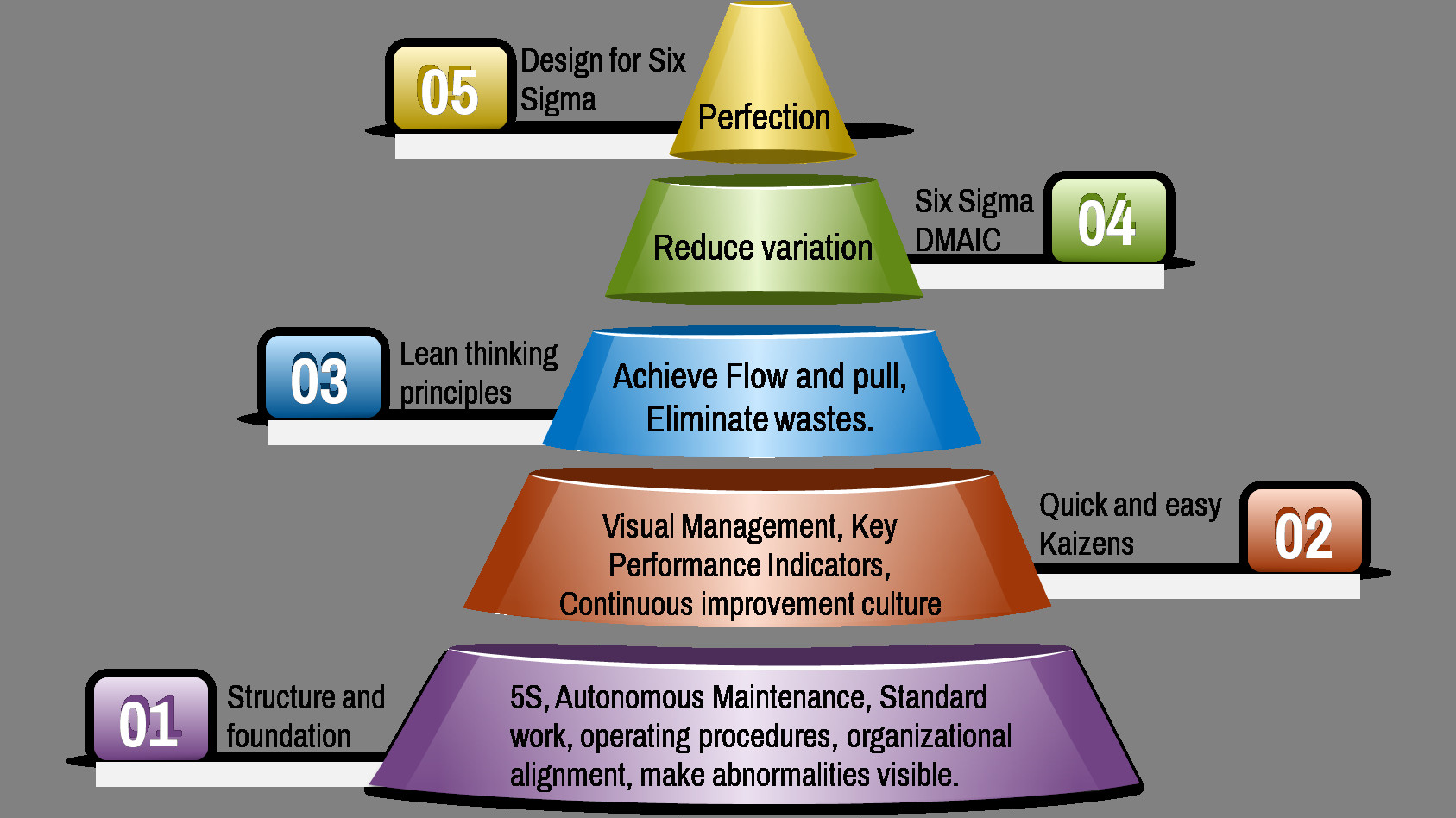

Five stages to place Lean in an organization

If your company has decided to embark on ‘Lean journey’, key question is how to begin and where to end? Though no two Lean placements are same, I have put together a pyramid to explain where you should start and end.

Stage 1 & 2: “Learn to see first” – Lay the necessary foundation – Remove sources of ‘Muri’ (Muri is a Japanese term used for physical strain).

Value Stream Mapping is a great tool which will help you ‘learn to see’ and a necessary foundation for Lean placement. It is important to ‘engage’ the workers to discover ‘how to make life simple’, using these Lean approaches, first. How much time will it take to do stage 1? If this is your question, I say ‘it depends’, on your company’s innate culture and current process maturity level. In stage 2 set up a good visually vibrant environment. People wish to see to believe, a good visual factory will create an environment. A keynote to the leaders is, equip employees with ‘Lean knowledge’ to make life simple first. Their belief in the philosophy is important to come by first. Belief is the starting point of any journey. Expecting ‘return on investment’ without fruitful engagement will burden employees; focus will shift from means to results. Without well understood and proven means, results cannot be achieved.

Stage 3: Apply to learn and learn to apply simultaneously – Remove Muda (a Japanese word for physical wastes or non value added time and efforts)

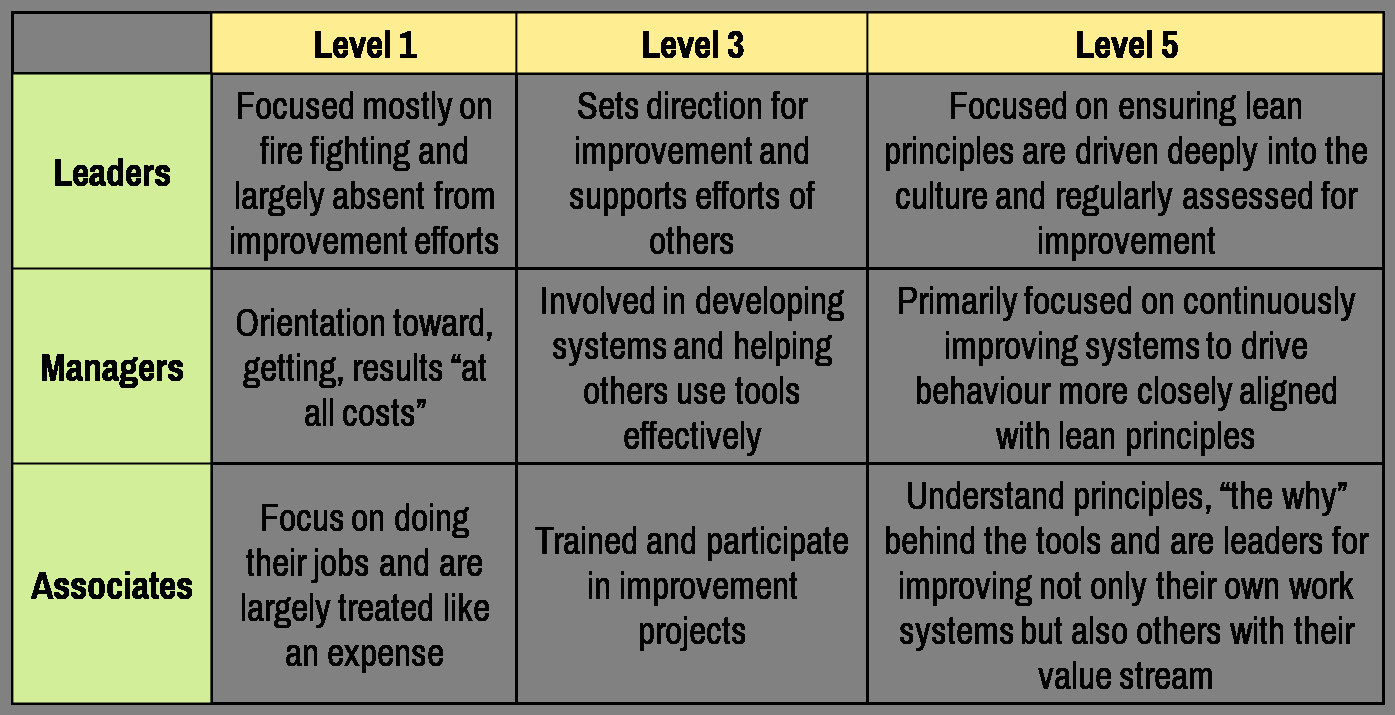

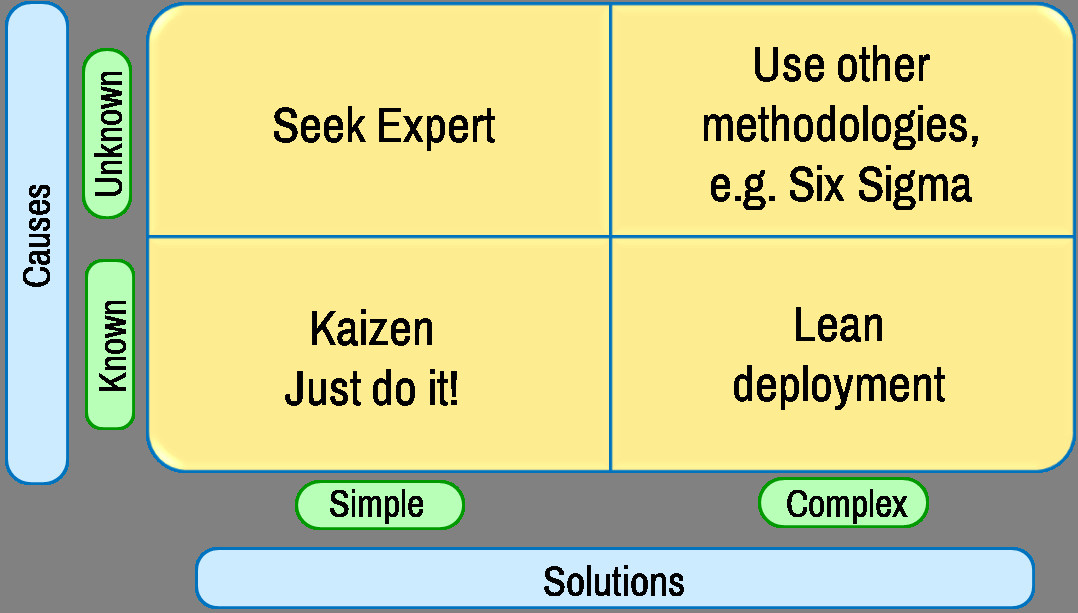

A company should first understand how and where Lean can help. Refer the figure below.

Cause to a problem is known (at least hypothetically) and solution is simple: Just fix the problem (Kaizen is a Japanese word meaning ‘change for better or good’). Do not complicate it with rounds of meeting, discussions and other such things. Try if it works great, if it doesn’t work, still great, you now know your perceptions of ‘solutions’ is wrong.

Cause to a problem is unknown and solution is simple: Seek expert support from the related subject matter area.

Cause to a problem is known (at least hypothetically) and solution is complex: Here you will need Lean deployment.

Cause to a problem is unknown and solution is complex: Use other methodologies such as Six Sigma.

Stage 4 & 5: Continue the gains by lessening variations in means and results – Remove Mura (a Japanese word used for ‘inconsistencies’)

‘Lean Six Sigma’, is a most commonly used term today, but the irony is it is least understood term as well. Let us first appreciate these two are two different approaches with different purposes. Lean focuses on ‘velocity’ while ‘six sigma’ focuses on ‘accuracy’. Which one first? Answer to this question depends on the business case and varies from company to company.

Use velocity of Lean culture to achieve actions at the speed of thought aligned to ‘time and productivity’ based goals. Use accuracy of Six Sigma to give direction to the efforts. If variation is not a problem, be happy with Lean and leave Six Sigma alone or use it where needed only.