Lean Six Sigma Green Belt

Training and Certification program in Lean Six Sigma Green Belt

37% of the organizations across the world employ Lean Six Sigma to achieve better Business results. The Lean Six Sigma course is designed to equip you with complex problem-solving skills, project management, change management and leadership skills. Most organizations now seek continuous improvement skills as a part of all the job roles. Training and Certification in Six Sigma will increase your market value by at least 2x times

Is this certification right for me?

Six Sigma is practiced in medium, large and multinational enterprises across the world as a continuous improvement methodology to achieve breakthrough enhancements and boost their profits. If you are looking for a job change, a certification in Six Sigma will boost

your chances of getting the job.

Lean Six Sigma Green Belt training and certification is highly recommended for those in Operations Excellence/ Operations/ Production/ Quality/ Inspection/ Management role. Knowledge in Lean Six Sigma can help you to improve Quality, Efficiency or Delivery.

Training and Knowledge in Lean Six Sigma at the Green belt level will enhance the way you perceive business and its strategy. It is a steppingstone for Middle and Senior management to later imbibe black belt skills

One of many success stories – How SKIL helped Sharath get promoted and go to

USA within an year of doing his Lean Six Sigma course

Sharath B S , Amazon, BI Engineer, Location – USA

He initially got trained as a Green Belt in Amazon. Amazon had hired SKIL to train some of its key resources on Lean Six Sigma concepts. He was among the participants. He wanted to learn more, he joined the Six Sigma Black Belt program with SKIL on his own. He would learn during the weekends and apply the learning to his job every day. Within no time his peers found a remarkable transformation in his skills in data analysis. He supported his US colleagues on Business Intelligence reports from India. The lady whom he supported from India, recommended Sharath as her replacement. When he received an offer letter from Amazon USA to join them as a Business Intelligence Engineer, Sharath’s joy knew no bound. He left for USA in 2016 and continues to grow in his career there.

He shared his success story with his friends and visited our office to personally share his success story with us. We are proud of Sharath, and we are proud of everyone who invests in themselves to take charge of their destiny. We are committed to serve such empowered individuals and are determined to do so for rest of our lives.

We salute Sharath and many such individuals who are determined to make a difference in their workplace.

Benefits of getting trained and certified as Lean Six Sigma Green Belt

Exceed expectations

Applying Lean tools will help you achieve breakthrough improvements in efficiency, quality and turnaround time in your own work area. You will exceed expectations with the use of Lean tools.

Job Security

Working professionals having skills in Lean have higher job security than others. Because as a Lean practitioner, you are always in a hunt to add value to your company

Get on A Team

Knowledge is one of the key criteria to consider for A team. With Lean knowledge, you have an edge over others!

Confidence and Self – Esteem

Once you achieve most of what is mentioned above, you will gain confidence. Lean credentials, success stories, more confidence, and getting into A team will boost your chances of getting hired in a global organization.

Why SKIL

Experience - Consulting hours

Professionals coached

Segments worked with

Career path options

Training & Certification in Lean enhances your existing job role. If you are keen to explore roles specific to Lean Management skills, you could consider:

- Lean Six Sigma Green Belt

- Lean Six Sigma Black Belt

- Business Analyst

- A career in process excellence.

- A career in operations excellence.

- Business excellence manager.

- Quality Assurance Manager.

- Continuous Improvement Manager.

- Operations excellence manager.

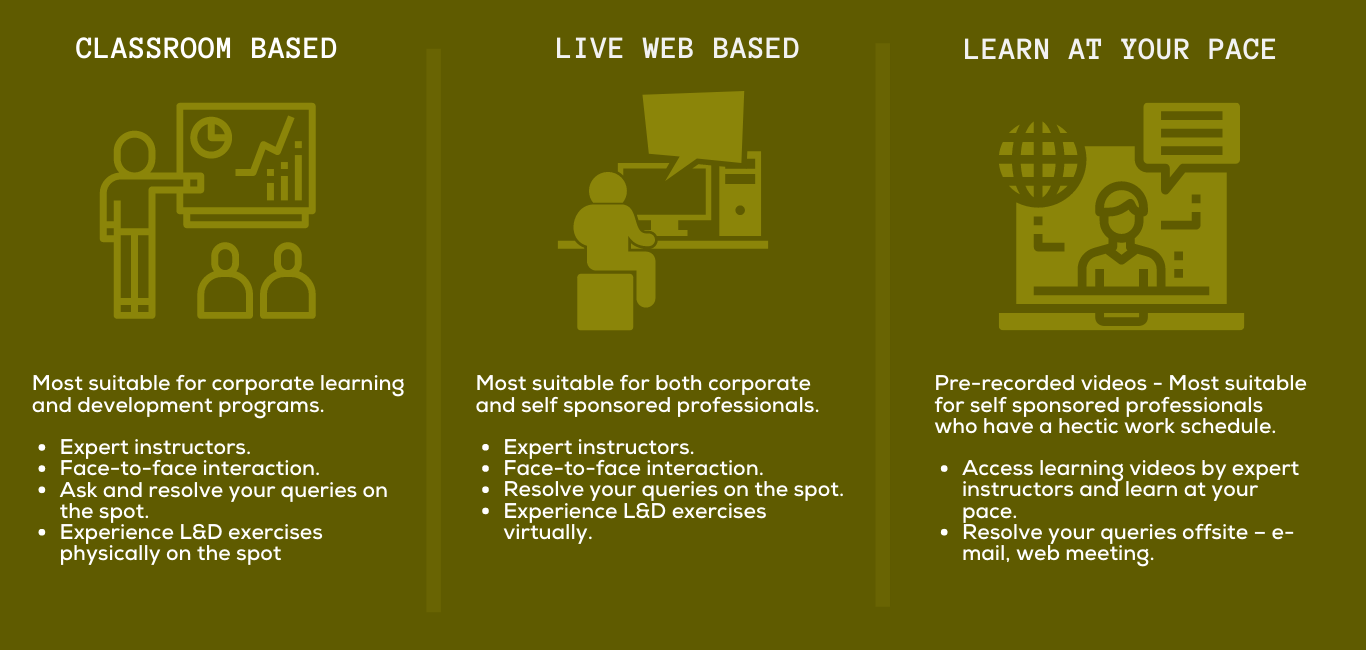

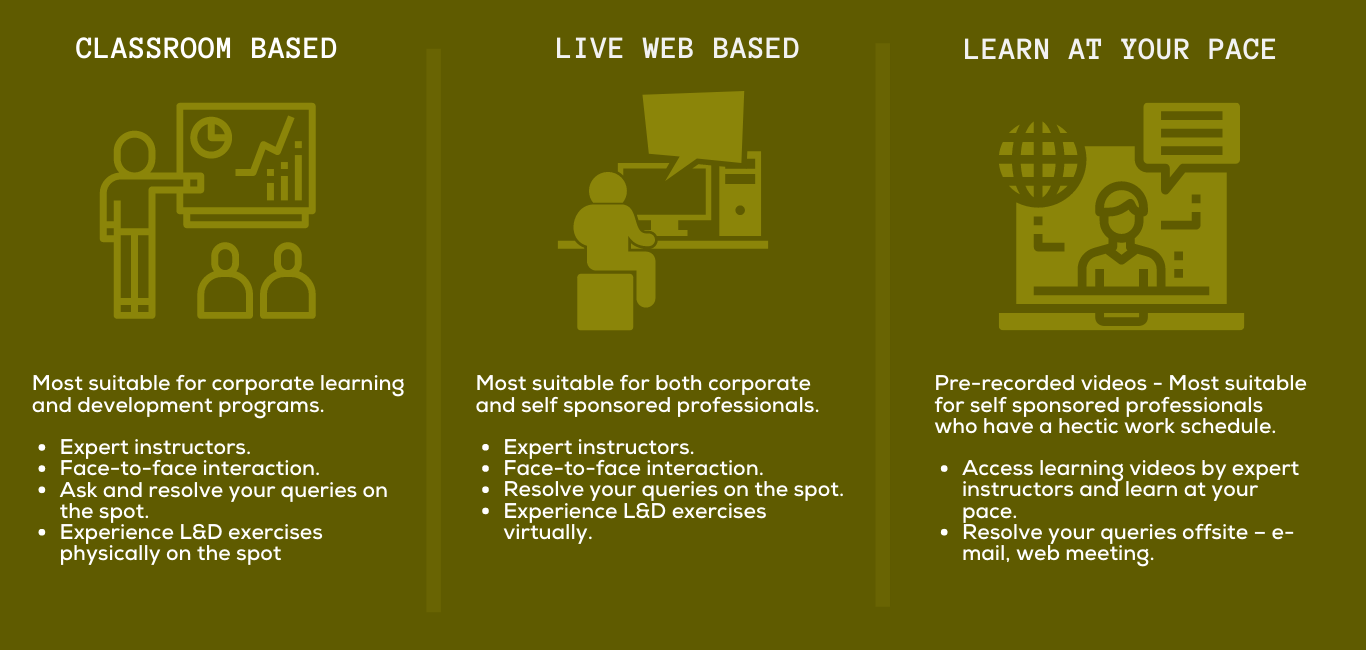

Course is delivered in three modes

Duration and Pre-requisites

Course Duration

- Classroom based – 5 days (weekends)

- Instructor-Led live web sessions & self-paced – 40 hours.

- Self-paced sessions – within 6 months

Work experience

- Work experience is necessary. A minimum of 2 years of experience is preferred.

- Understanding of business cycle is required.

Education

- Preferred Minimum education – Graduate from any university

- Diploma/ Graduate

- Post Graduate/ Masters

Body of Knowledge

How to define a problem?

- Discover trivial many and vital few using Pareto diagram.

- Learn the best way to measure performance using Sigma measures.

- Know how is the data distributed using Histogram.

- Learn how to understand a process at a glance using SIPOC.

- Learn how to develop a Project Charter for your project.

- Develop storyboard for stakeholder alignment and understanding.

How to measure the current state?

- Learn cause and effect relationships using cause and effect matrix.

- Learn how to plan data collection using Check sheet and stratification.

- Discover various types of data using types of data.

- Measurement system analysis – Attributes data only.

- Map ‘as is’ process using Flow charts, Swim Lane mapping, Standard Work.

- Assess probability of success or failure using Normal Probability Distribution.

- Line plots, Box and whisker plots.

- Develop storyboard for stakeholder alignment and understanding.

How to ‘discover the root cause’?

- Learn how to find root cause to any problem using 5 why analysis.

- Fault tree analysis to arrive at the root cause.

- Scatter diagrams to study the nature of relationship between two variables.

- Correlation analysis to study the strength of relationship between two variables.

- Simple linear regression to predict a response variable.

Develop storyboard for stakeholder alignment and understanding.

- How to develop, implement and validate solutions?

- Mistake proof errors using Poka – Yoke.

- Learn to design and run experiments using One-way Analysis of Variance.

- Develop storyboard for stakeholder alignment and understanding.

How to sustain results?

- Develop a Control plan to ensure sustenance of results.

- Develop storyboard for stakeholder alignment and understanding.

How to define a problem?

- Lean thinking principle – Value, to identify value in a process.

- Efficiency and productivity definitions.

- Time measurement definitions.

- TAKT time to evaluate process flow versus customer demand.

- A3 problem solving approach to document your improvement storyboard.

How to measure the current state?

- Lean thinking principles – Value stream and Flow, balance and demand.

- How to Measure Efficiency / Productivity / Timeliness.

- Five golden rules of Gemba in problem solving.

- Analyze the current state using – Muda (8 types of wastes), Mura and Muri.

- How to analyze work using Work analysis chart?

- Map the current state using principles of Current State Value Stream Mapping.

- Compare TAKT time to Line Balance and Flow to identify bottlenecks.

- Design and launch Point Kaizen programs.

- Develop storyboard for stakeholder alignment and understanding.

How to design the future state?

- Lean thinking principle – Pull to design the future state for Just in time production.

- Standard work to capture gaps in the current state and design future state.

- Kanban to regulate material and information flow in future state design.

- Andon principles to assist in future state design.

- Jidoka principles to assist in future state design.

- Principles of Single Piece Flow to assist future state design.

- Cellular Flow principles to assist future state design.

- Develop storyboard for stakeholder alignment and understanding.

How to implement the future state?

- Principles of Lean thinking – Pull and ideal state considerations.

- Gemba rules to successfully drive implementation efforts.

- Develop storyboard for stakeholder alignment and understanding.

How to sustain the results?

- Learn the concepts of PDCA to sustain results.

- Visual factory and standard work principles to sustain results.

- Document the learning using one point lessons to sustain results.

- Develop storyboard for stakeholder alignment and understanding.

- Introduction to team management.

- Different types of teams and their application areas.

- Learn Team communication principles.

- Basic principles of making a presentation.

- How to make effective presentation?

- The do’s and don’t s of presentation.

- Basic principles of effective communication.

- The do’s and don’t s of communication.

During the entire course you will be using following applications to analyze data

- Microsoft Excel.

- Sigma Excel.

- Minitab.

Key features of the program

Placement Assistance

Certification exam included

Expert course design

Free “Lean Made Simple” book

Learn by doing – Exercises & Games

4 hrs of coaching and mentoring