“The most dangerous kind of waste is the waste we do not recognize” – Shingo

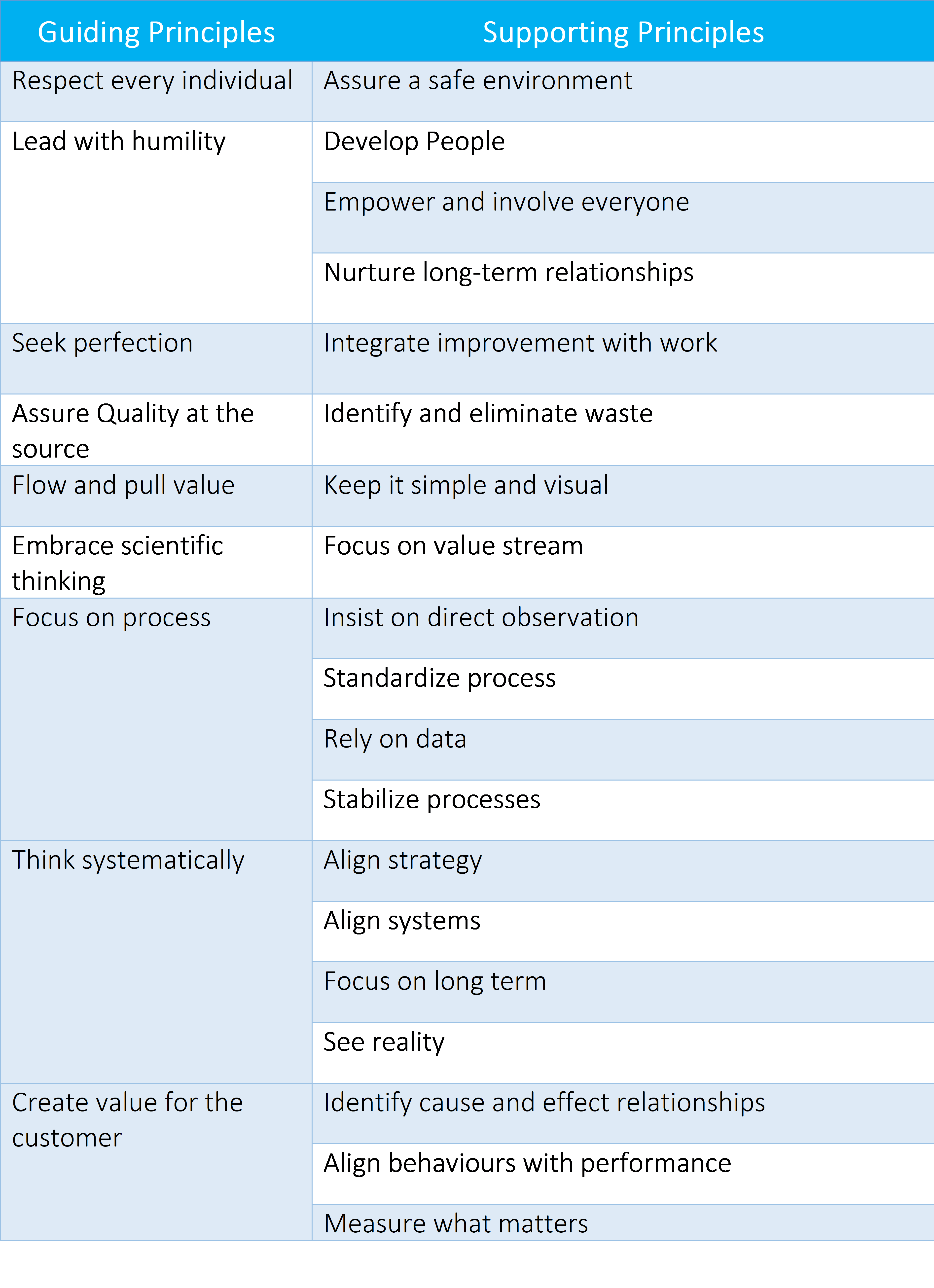

Shigeo Shingo was born in Saga City, Japan. He was a Japanese industrial engineer. Shingo is known as the global leading expert on the Toyota Production System (TPS). According to him, these guiding principles make Lean or TPS successful:

Table 1 – Guiding and supporting principles

Shingo Principles, Lean Behavior and Attitude

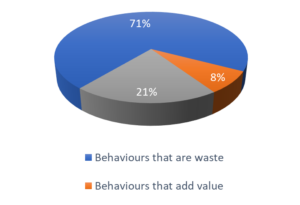

It is not possible to achieve Lean results if fat behaviour exists in the workplace. As a result, many companies use Lean implementation with ease to eliminate fat behaviour. Bob Emiliani discovered a correlation between behaviour and wastes in an organization. Above all, he found that while waste behaviour produces wasted effort, Lean behaviour produces Lean results. It is important to note that fat behaviour can manifest in many ways. For instance, it includes micromanagement, bullying, blame, and politics.

Figure 1 – Fat behaviour produces waste! – Source: Bob Emiliani

Lean Attitude – The Toyota Way

These are the Lean attitudes that make Lean implementation successful:

- Above all, make sure the customer is always first.

- Additionally, meet challenges with courage and creativity to realize your vision.

- Kaizen: Improve business operations continuously. Additionally, always drive for innovation and evolution.

- Genchi Genbutsu: in other words, ‘go and see’.

- Shitsujitsu Goken: to clarify, it means ‘spend money wisely’.

- Team Work

- Ownership and Responsibility

- Humility and Gratitude

- Integrity

- Lastly, and most importantly, remember the motto – ‘We love our company!’